Maximize yield with efficient product handling.

Swiss cheese, raw ham, bacon – when it comes to processing non-uniform natural products, the smallest details can make a significant difference in your production's overall profitability. Maximizing yield is important as it represents real money. Getting the most out of your product depends on various factors and requires know-how.

Product feeding and slicing technology.

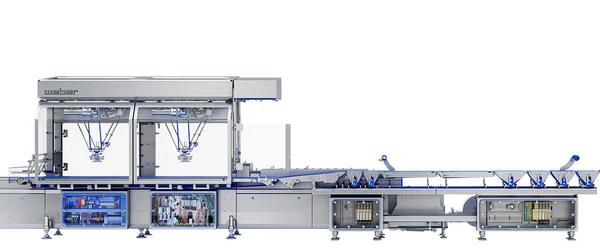

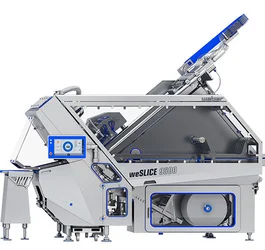

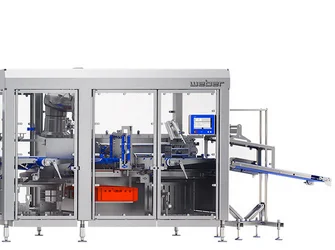

When you hear “Weber”, slicers immediately come to mind. Nowadays, you know us as a leading solutions provider for complete slicing and packaging lines. Since we made our name in the slicing sector back in the 1980s, Weber has been setting standards in the food processing industry ever since. It all began in 1986 with the Weber Slicer CCS 7000. With the development of our first slicer, we disrupted the slicing machine market once and for all. Constructed entirely of stainless steel, this slicer had a new, revolutionary concept of hygiene and a performance capacity that far surpassed other machines on the market. What's more, the Weber Slicer CCS 7000 was able to do something that no other machine had been able to do before: Precision slice the Swiss specialty “Bündnerfleisch”. This represented a milestone in the slicing technology industry and cemented our leading position in the slicer market. Today, the Weber slicer portfolio offers a wide range of slicers for different performance classes, automation levels, and applications.

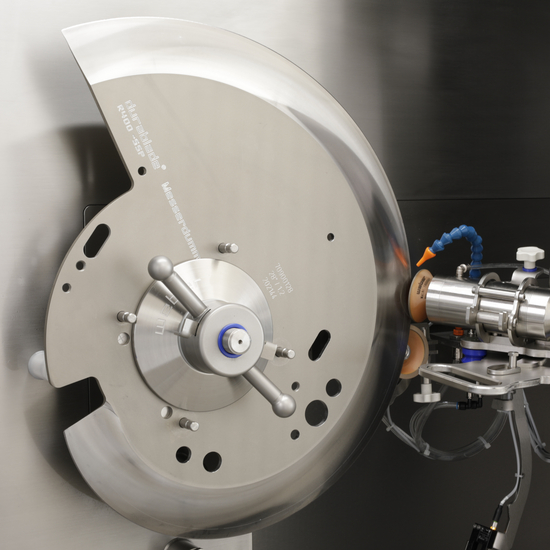

Details are crucial in ensuring that our slicers can develop their full potential. Product feeding and product grippers play a key role in achieving perfect slicing results. Even if your product has been perfectly prepared, accurately measured, and weighed, if the infeed to the slicer is not clean, even the best preparation will be in vain. And you lose money as a result. That's why at Weber, we rely on servo technology to guarantee precise and stable infeeding of your product to the slicer's cutting edge. Our optional vario technology can even provide track-specific control. The number of slices, slice thickness, and portion weight can be controlled independently on each track. This maximizes yield and achieves well-balanced portions with minimal give-away, even with products that are not perfectly calibrated or when products are fed into multiple tracks. Product yield can be further increased by using vacuum grippers rather than needle grippers. Vacuum grippers can also be used for track-based feeding. Additionally, vacuum grippers increase yield for a variety of products such as cheese, as end piece sizes are significantly reduced.